WPC Crunching the Numbers

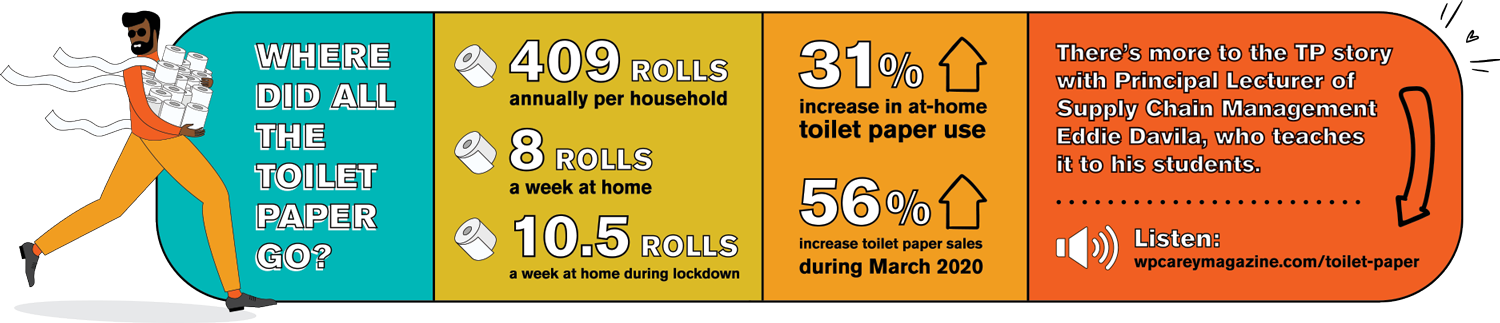

Disruptions from COVID-19 put supply chains front and center in the minds of business leaders and consumers alike. Suddenly, everyone is asking: How reliable is our supply chain? What do we need to strengthen it? And why are everyday goods in short supply? With so much attention focused on supply chains, these numbers can help explain some of the people and processes that produce and distribute products.

An executive order issued by the White House in February addresses vulnerabilities in the supply chain for four groups of critical goods: semiconductor manufacturing and advanced packaging; large-capacity batteries (such as those used for electric vehicles); critical minerals and materials; and active pharmaceutical ingredients (APIs).

A global Gartner survey in February of more than 1,300 supply chain professionals found that 87% of respondents plan investments in supply chain resiliency — the ability to adapt to structural changes by modifying supply chain strategies, products, and technologies — within the next two years.

The Gartner survey also showed that even more supply chain professionals (89%) want to invest in agility — the ability to sense and respond to unanticipated changes in demand or supply quickly and reliably, without sacrificing cost or quality.

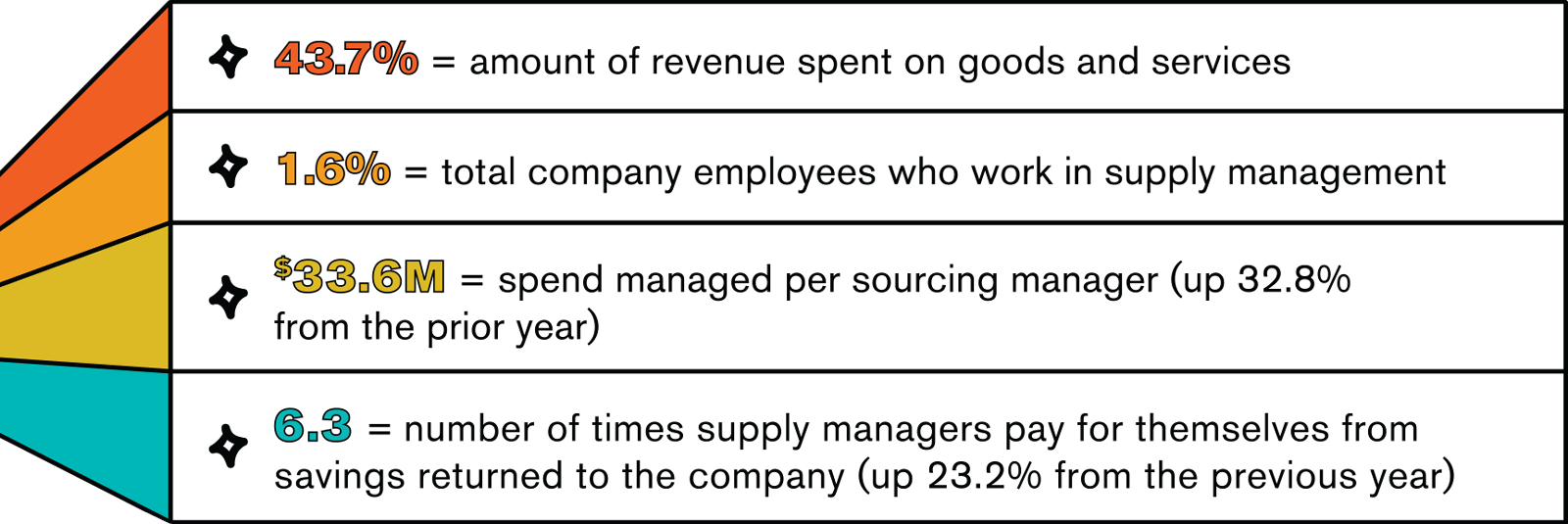

According to a recent survey of supply management leaders at Fortune 1000 companies by CAPS Research (Center for Advanced Procurement Strategy), a research center at ASU:

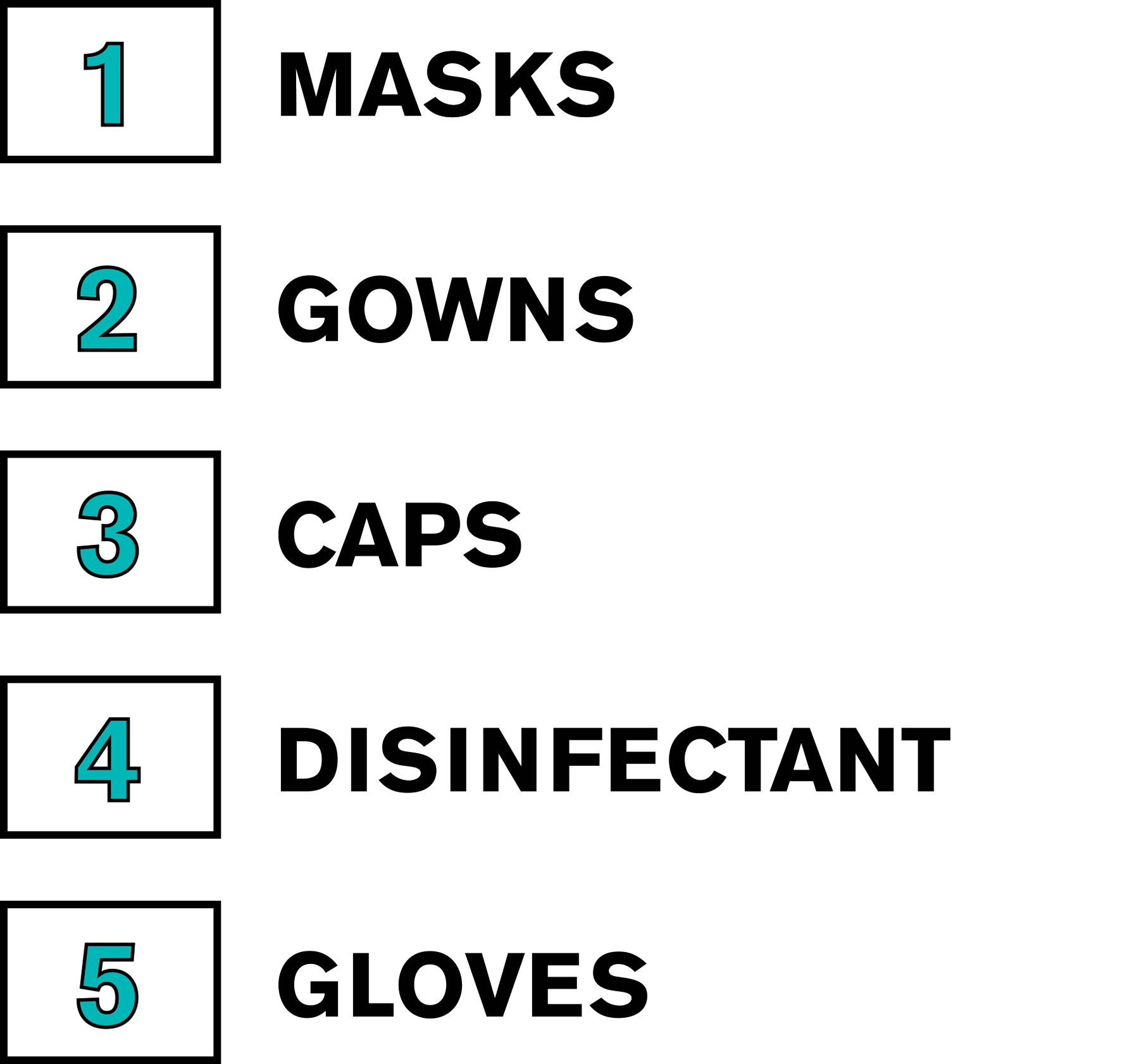

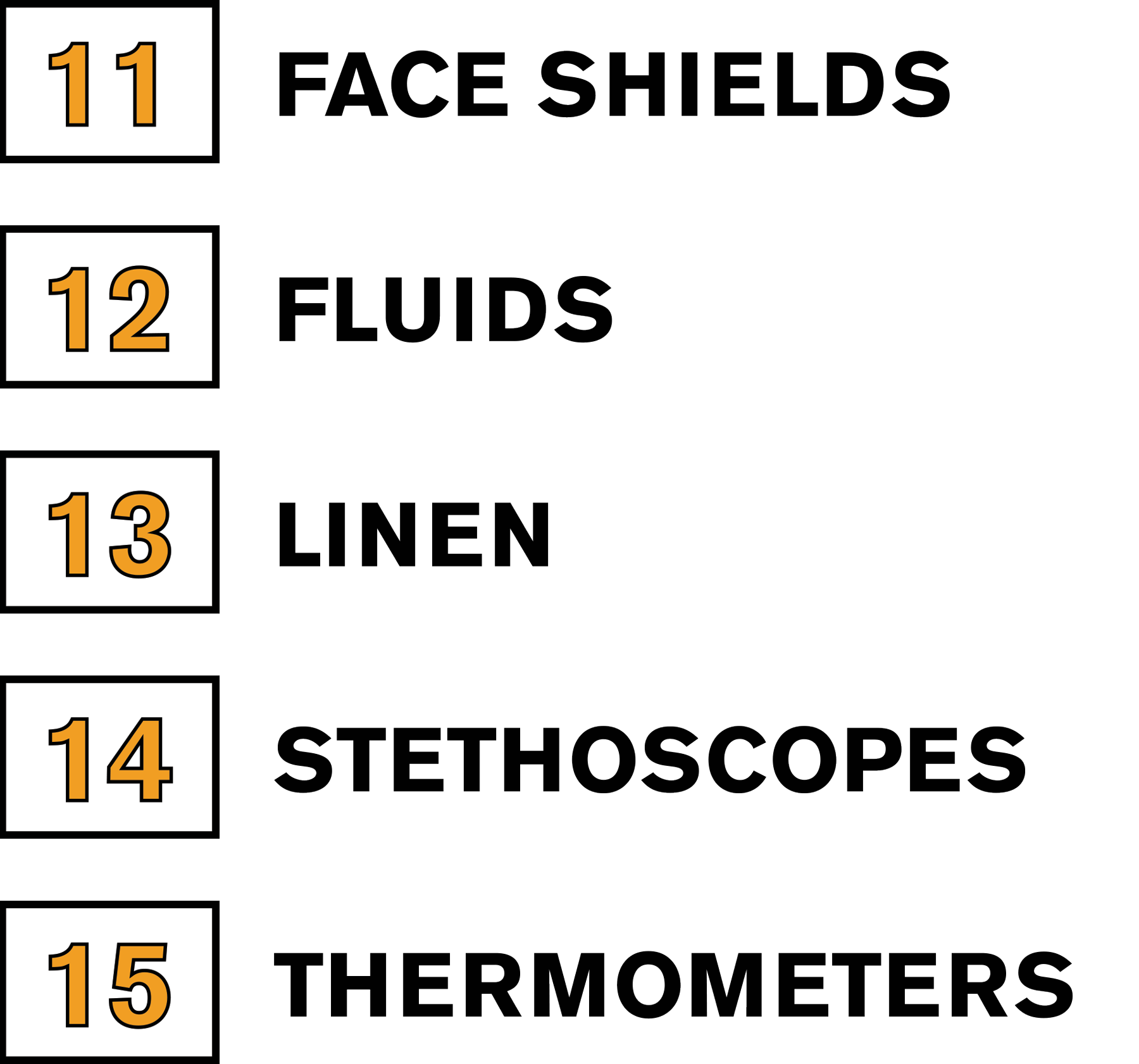

Early in the pandemic, supply chain failures were mostly related to personal protective equipment (PPE). The solution: Professor of Supply Chain Management Eugene Schneller’s paper, A Commons for a Supply Chain in the Post-COVID-19 Era: The Case for a Reformed Strategic National Stockpile.

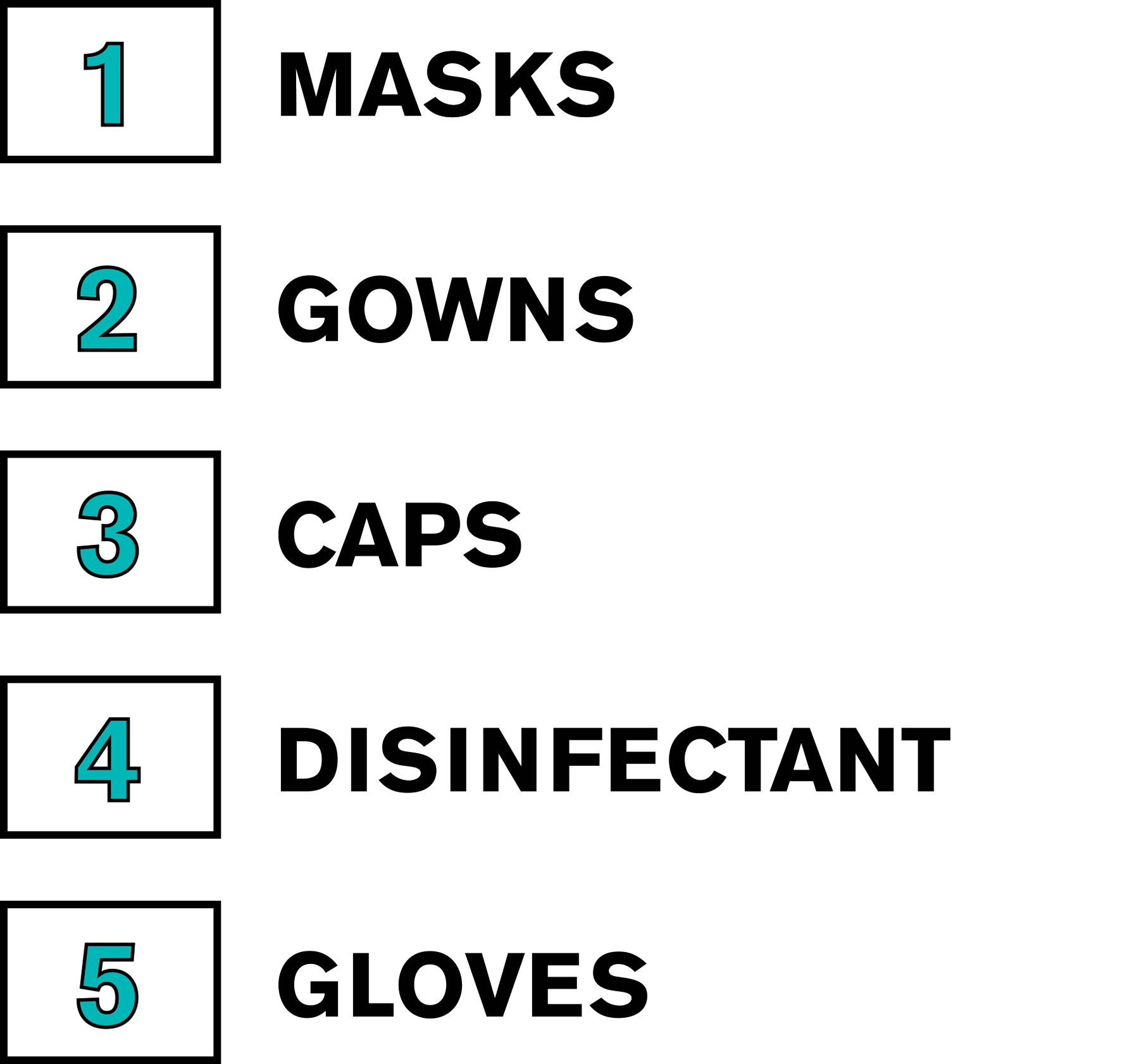

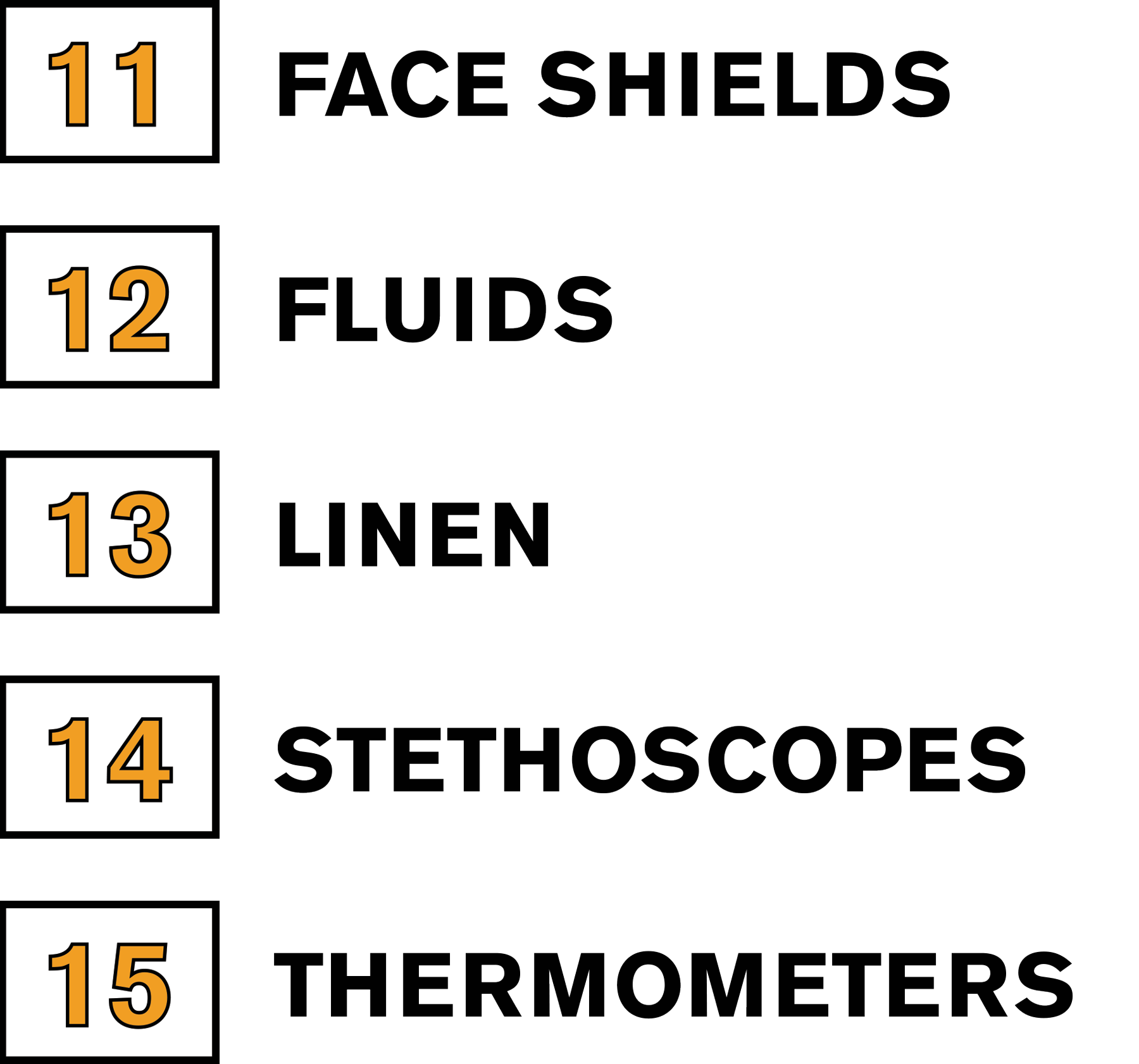

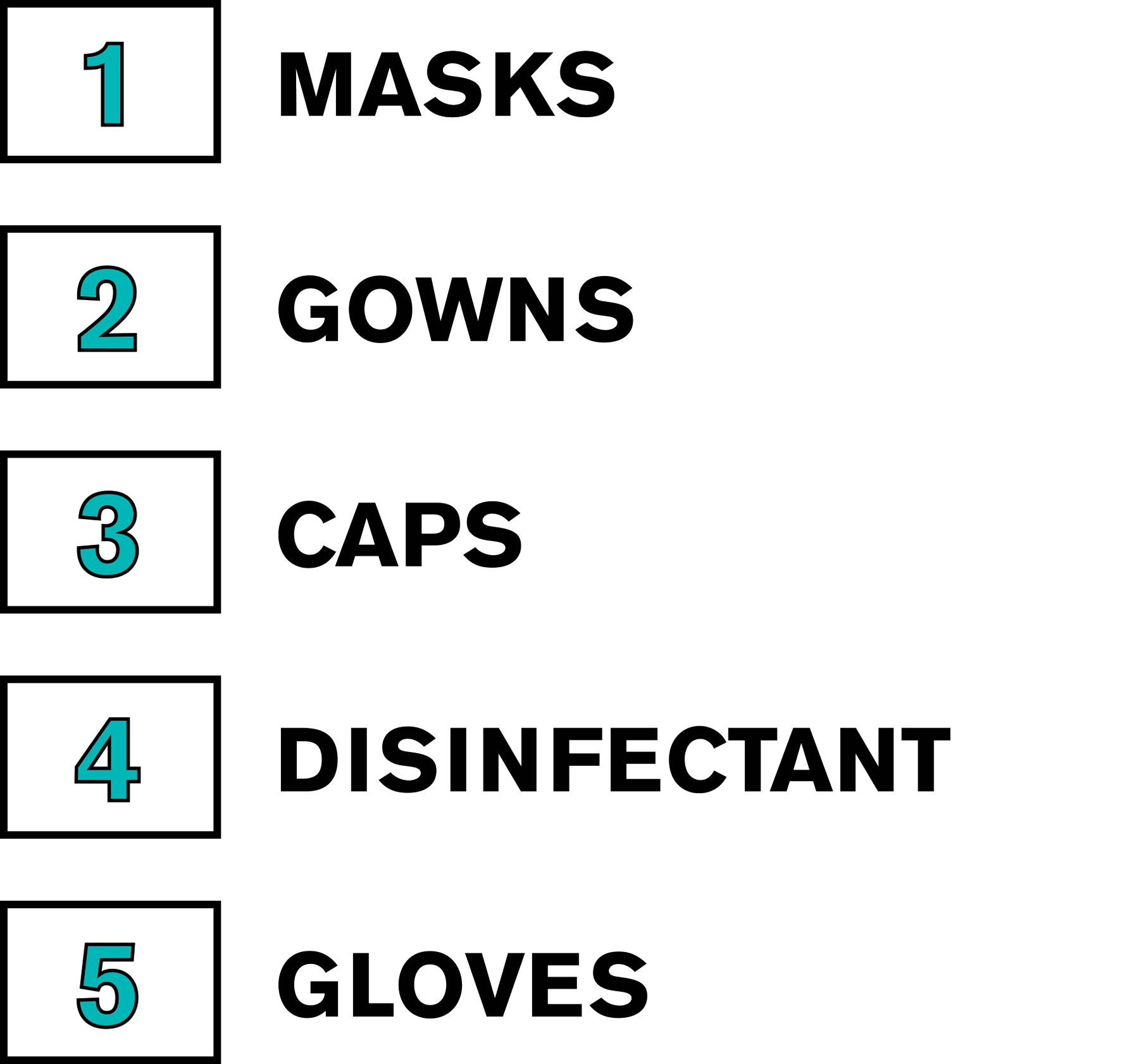

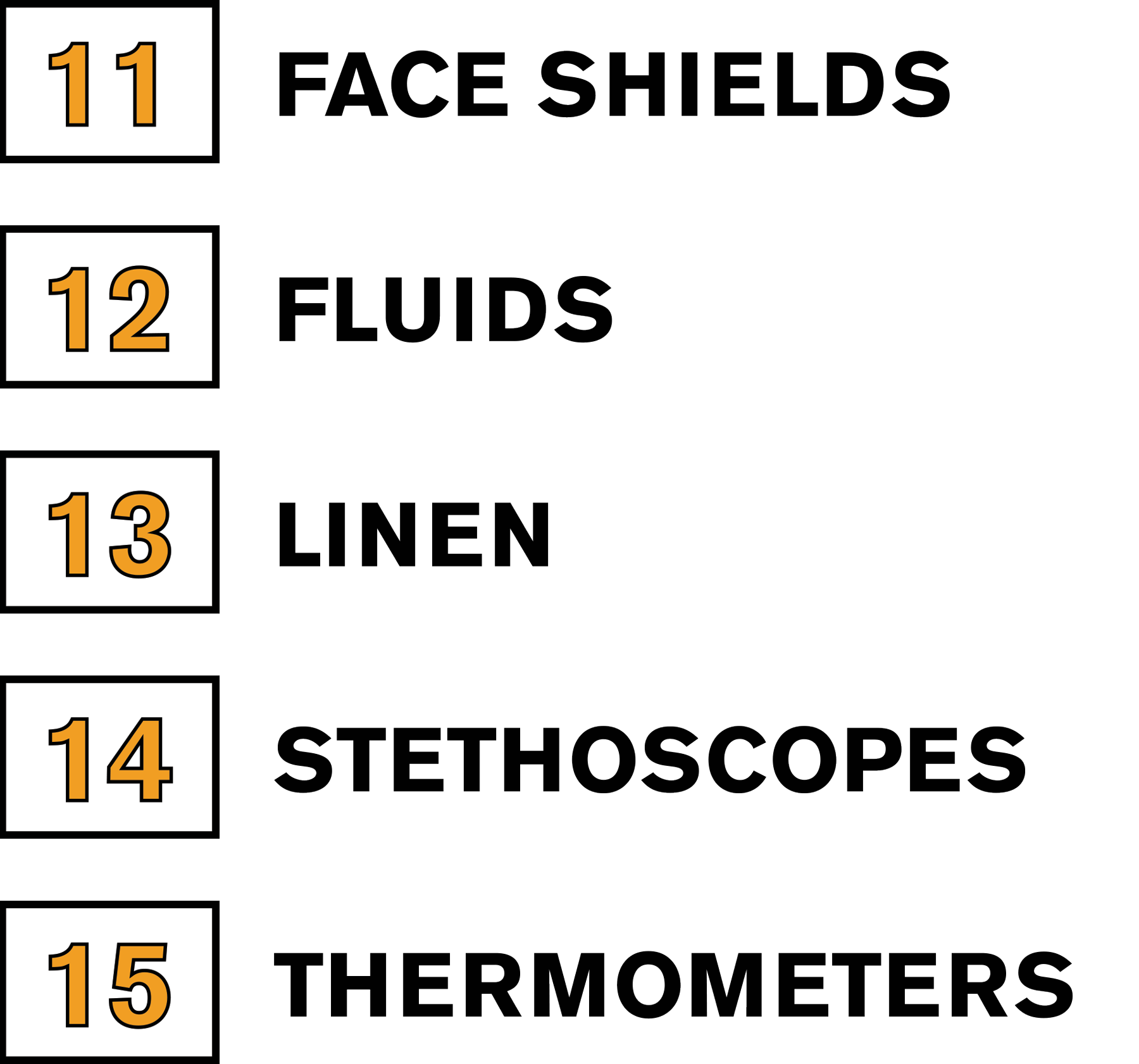

Below are the 20 most common PPE item category shortages experienced by hospitals in Arizona during the height of the pandemic, many of which were common to hospitals across the United States.